-40%

4 Vintage Metal King Seeley Thermos - 3 Tartan Plaid Colors & 1 Game Birds

$ 13.2

- Description

- Size Guide

Description

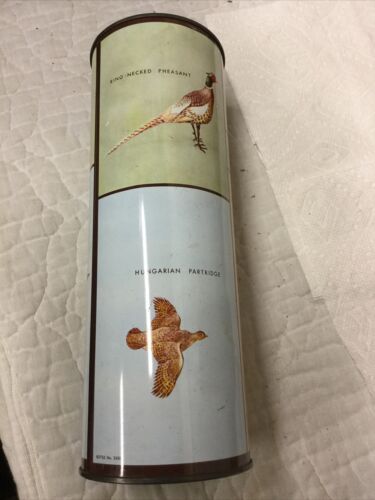

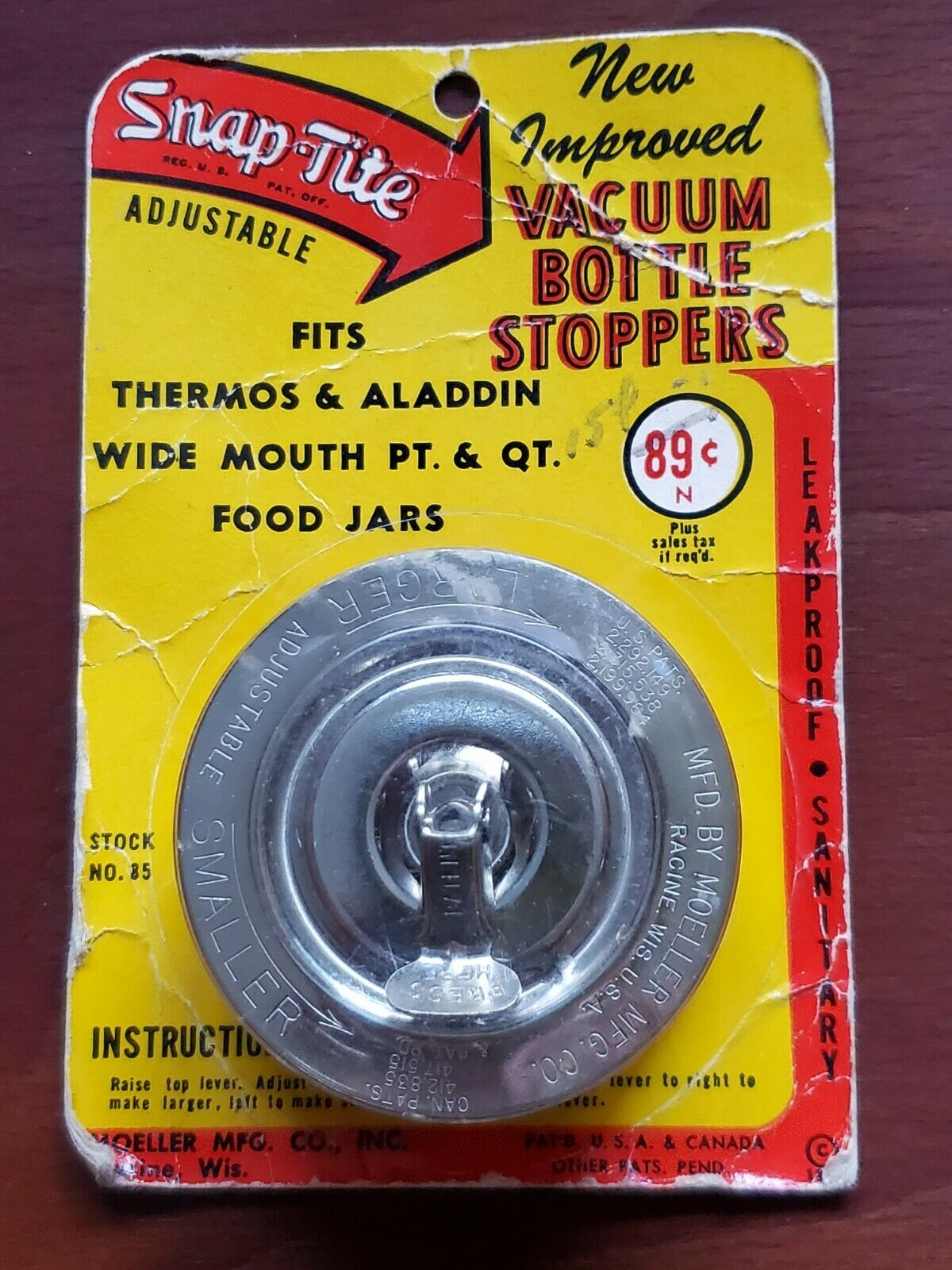

4 Vintage Metal King Seeley Thermos - 3 Tartan Plaid Colors & 1 Game Birds. 2 of the plaid color and the game birds are quart size, 1 of the paid color is the smaller pint size. The game birds thermos is just the metal lithograph steel - no inner glass liner and no top. The 3 plaid thermoses are fine complete. Please see my 12 photos. The buyer gets the 3 complete plaid color thermos lot and the 1 game birds shell.History of the Thermos Company

Invented in 1892 by Sir James Dewar, a scientist at Oxford University, the "vacuum flask" was not manufactured for commercial use until 1904, when two German glass blowers formed Thermos GmbH. They held a contest to name the "vacuum flask" and a resident of Munich submitted "Thermos", which came from the Greek word "Therme" meaning "hot".

In 1907, Thermos GmbH sold the Thermos trademark rights to three independent companies: The American Thermos Bottle Company of Brooklyn, NY; Thermos Limited of Tottenham, England; Canadian Thermos Bottle Co. Ltd. of Montreal, Canada. The three Thermos companies operated independently of each other, yet developed the Thermos vacuum flask into a widely sought after product that was taken on many famous expeditions, including: Lieut. E.H. Schackelton's trip to the South Pole; Lieut. Robert E. Peary's trip to the Arctic; Colonel Roosevelt's expedition to Mombassa and into the heart of the African Congo with Richard Harding Davis. It even became airborne when the Wright Brothers took it up in their airplane and Count Zepplin carried it up in his air balloon.

Thermos was hailed around the world for its revolutionary design. In 1909 Thermos won the "Grand Prize Award" at the Alaska Yukon Pacific Exposition and went on to be honored at 7 other world expositions. The Thermos vacuum flask made a technological breakthrough in 1911 when Thermos Limited of England produced the first machine-made glass filler. Today Thermos continues to be the world leader in glass vacuum technology.

With the production of machine-made glass fillers, the popularity of Thermos products grew tremendously. Demand grew so much that The American Thermos Bottle Company moved in 1910 from Brooklyn, NY to Manhattan to triple output and then moved again in 1912 to Norwich, CT, again to increase output. The move to Norwich allowed Thermos to improve productivity, clear the backlog of orders and reduce prices in 1914 and 1915. In 1918, the president of The American Thermos Bottle Company, William Walker, announced plans to build manufacturing and distribution facilities all over the world. With an increase in capital by the shareholders, the company entered a period of expansion. Unfortunately, the stress of a general business recession in the early 1920's caught up to Walker and he died in 1922. His widow ran the company briefly and then sold the family interest in 1923 to a syndicate formed by Tobey and Kirk, a firm of investment brokers and bankers. Business began to pick up with the introduction of the No. 24 pint sized "Blue Bottle" and a new gallon-sized insulated food jar known as the Thermos Jumbo Jug.

In 1925 Thermos merged with a small competitor, the Icy-Hot Bottle Company of Cincinnati, Ohio.

A new type of vacuum-insulated double-walled Pyrex® glass vessel was engineered in 1928, some as large as 28 gallons. These became extremely popular in 1928 and 1929 for ice cream cabinets and frozen fish cabinets, just prior to the advent of commercial refrigeration.

Thermos Limited in England had nearly shut down because of the war. After the war the company continued to struggle for some years, operating not as a manufacturer, but as an assembler of imported components. By 1931 the production of glass fillers restarted and the company began its economic recovery. Also, a metal canister factory was opened at Leyton in 1932 and glass filler production was moved to that location in 1938. When World War II broke out in Europe in 1939, virtually all of the capacity of Thermos Limited in England was changed over to wartime requirements of the British military forces. Every time a thousand bombers went out on a raid, 10,000 to 12,000 Thermos vacuum flasks went with them. Meanwhile in the U.S., The American Thermos Bottle Company played an important role in the war. More than 98% of its output was for military usage and atomic energy laboratories.

When the war ended in 1945, Thermos plants were reconverted to civilian and peacetime uses. Demand was so great that the Norwich factory, operating at full capacity, could produce only the standard items. Pre-war specialty products did not reappear until later with the purchase in 1947 of a plant in nearby Taftville for metal manufacturing.

In 1952, The American Thermos Bottle Company acquired controlling stock in The Plastene Corporation in Crawfordsville, IN, a manufacturer of injection molded plastic products. This acquisition gave Thermos 2 injection molding facilities in the U.S., and greater expertise in this emerging technology. In 1953, a subsidiary company, Plastene Ltd. of Canada, was formed to produce molded plastic parts for Canadian Thermos.

Branching out further in 1955, The American Thermos Bottle Company acquired control of Hemp and Company, Inc. of Macomb, IL, manufacturers of the "Little Brown Jug" and other insulated jugs and chests as well as Duncan Hines outdoor grills. To reflect the growing diversity of products, the names of the North American companies were changed in 1956. The American Thermos Bottle Company became The American Thermos Products Company, and the Canadian Thermos Bottle Co. Ltd. changed its name to Canadian Thermos Products Limited.

In 1957, 50 years after the company started in the U.S., U.K. and Canada, the Thermos brand vacuum bottle was known almost universally for use with food and beverages. But it also proved useful in science, medicine and industry. It had been used in various instruments measuring electric power, rate of climb in airplanes, detection of oil deposits and weather recording. It had also been used to transport rare tropical fish and to preserve and transport blood plasma, serums, bones, tissues and insulin.

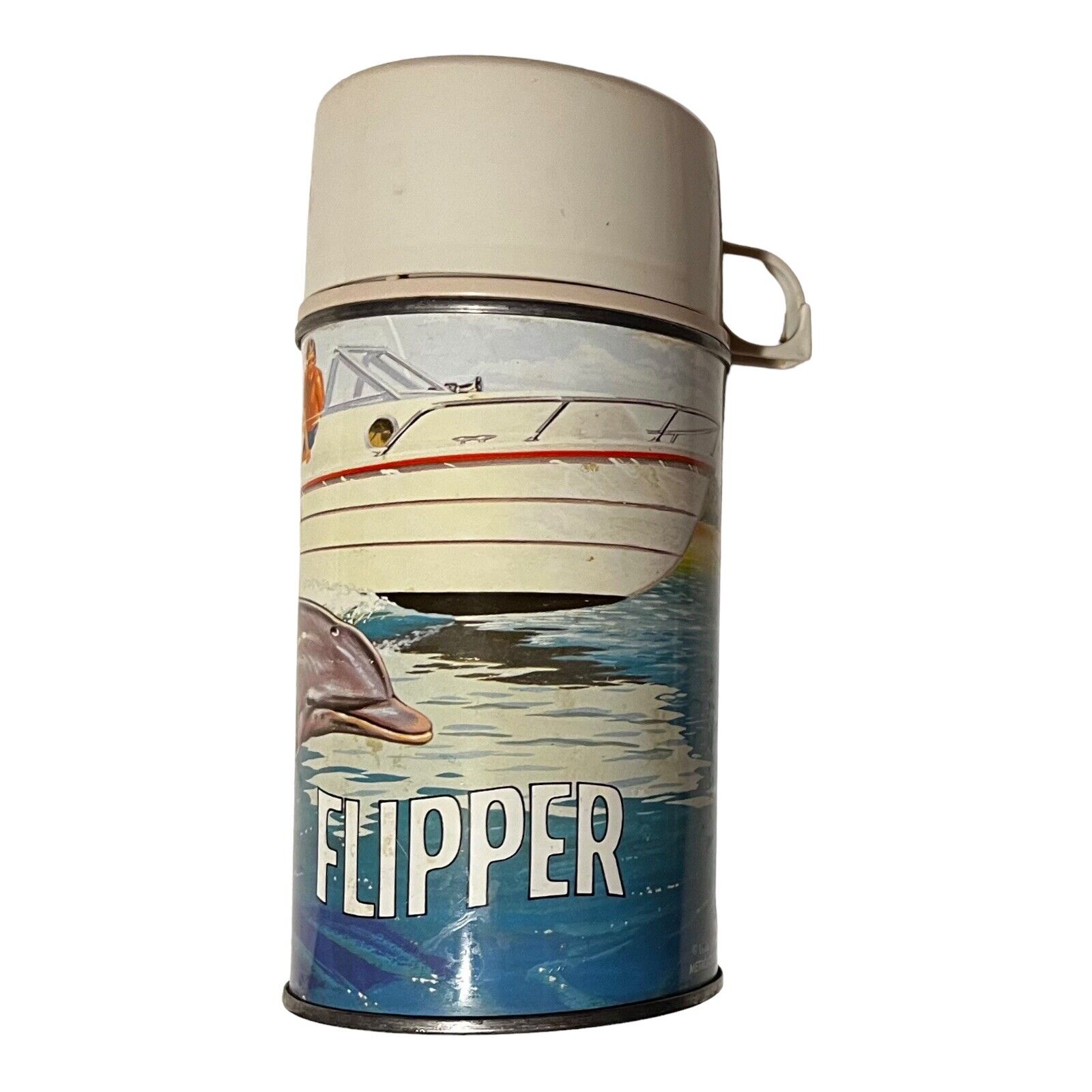

During the first 50 years, Thermos had a relatively stable ownership. In the next three decades there were three major ownership changes. In 1960, the U.S., U.K. and Canadian companies were purchased by the King-Seeley Company to form the King-Seeley Thermos Company. In 1965, King-Seeley Thermos purchased Structo Manufacturing of Freeport, IL, a manufacturer of outdoor cooking grills. Ownership changed hands again in 1968 when King-Seeley Thermos Company became a wholly owned subsidiary of Household Finance Company of Chicago, which later became Household International. That corporation was attempting to diversify outside its consumer finance business and eventually bought and sold companies involved in transportation, retailing and manufacturing.

By 1971, over 50% of the production of Thermos Limited of England was being exported to over 100 different companies. The company was presented with the Queen's Award to Industry for these export achievements.

The U.S. operation continued to expand. In 1972, an additional parcel of land was purchased at the Taftville, CT operation and the following year an adjoining building was purchased. In 1974, a second addition was built onto the Macomb, IL plant.

In 1982, as part of a parent company reorganization, the King-Seeley name began to be replaced by Household International. In 1983, Household expanded its manufacturing holdings by acquiring the Wallace Murray Company. The combined operation came to be known as Household Manufacturing. For the next 6 years, Household restructured its manufacturing operations. Several production facilities were moved from northern U.S. locations where they had been long established, to sites in various southern states.